Vacuum Pressure Leak Test . The essential guide to vacuum leak detection. Enclose sample in sealed an tight chamber. Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. A vacuum decay leak test evacuates air from the part or assembly to detect leaks. To ensure and maintain the pressure/vacuum; Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. This is certainly the case with leak detection, with four main methods being employed: Ensure you have the necessary. Tightness (or “the absence of leaks”) is required for numerous reasons, including: In addition, we distinguish, based on the direction of flow for the fluid, between the.

from www.youtube.com

Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. This is certainly the case with leak detection, with four main methods being employed: Enclose sample in sealed an tight chamber. Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Ensure you have the necessary. In addition, we distinguish, based on the direction of flow for the fluid, between the. Tightness (or “the absence of leaks”) is required for numerous reasons, including: The essential guide to vacuum leak detection. To ensure and maintain the pressure/vacuum;

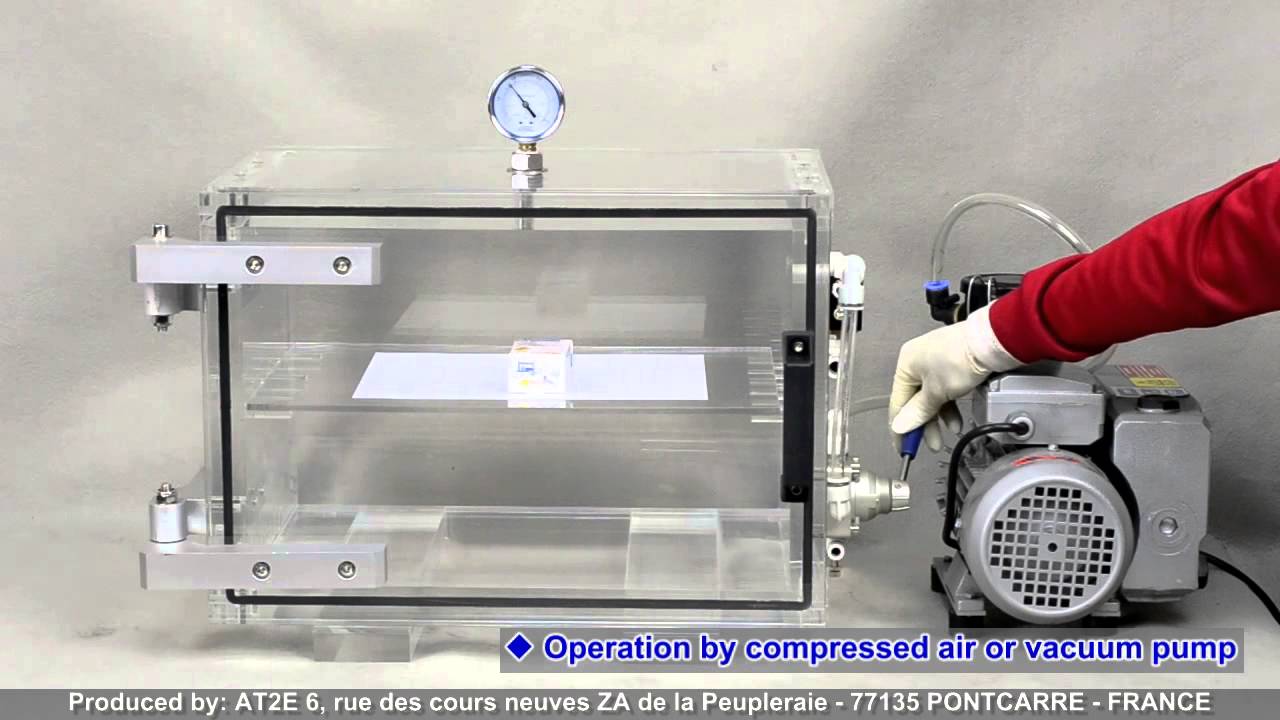

VLT ECO Vacuum Leak Tester (Eco Model) Tetra Pak test / Test d

Vacuum Pressure Leak Test Tightness (or “the absence of leaks”) is required for numerous reasons, including: Ensure you have the necessary. A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Enclose sample in sealed an tight chamber. In addition, we distinguish, based on the direction of flow for the fluid, between the. To ensure and maintain the pressure/vacuum; This is certainly the case with leak detection, with four main methods being employed: Tightness (or “the absence of leaks”) is required for numerous reasons, including: Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. The essential guide to vacuum leak detection.

From www.youtube.com

Leak Testing Methods Part 1 Vacuum Chamber Leak Testing InsideOut Vacuum Pressure Leak Test Ensure you have the necessary. Tightness (or “the absence of leaks”) is required for numerous reasons, including: To ensure and maintain the pressure/vacuum; In addition, we distinguish, based on the direction of flow for the fluid, between the. The essential guide to vacuum leak detection. This is certainly the case with leak detection, with four main methods being employed: Vacuum. Vacuum Pressure Leak Test.

From www.desertcart.com.kw

Buy Handor 14pcs Radiator Pressure Leakage Tester Tool Kit, Vacuum Vacuum Pressure Leak Test The essential guide to vacuum leak detection. Tightness (or “the absence of leaks”) is required for numerous reasons, including: A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Ensure you have the necessary. To ensure and maintain the pressure/vacuum; In addition, we distinguish, based on the direction of flow for the fluid, between the.. Vacuum Pressure Leak Test.

From www.ebay.com

Powerbuilt Automotive Vacuum & Pressure Testing and Bleed Kit 648532 Vacuum Pressure Leak Test This is certainly the case with leak detection, with four main methods being employed: Enclose sample in sealed an tight chamber. To ensure and maintain the pressure/vacuum; Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. Vacuum decay testing is as sensitive as pressure. Vacuum Pressure Leak Test.

From www.leybold.com

What is a leak and how to measure the leak rate in vacuum systems Leybold Vacuum Pressure Leak Test To ensure and maintain the pressure/vacuum; This is certainly the case with leak detection, with four main methods being employed: In addition, we distinguish, based on the direction of flow for the fluid, between the. Tightness (or “the absence of leaks”) is required for numerous reasons, including: A vacuum decay leak test evacuates air from the part or assembly to. Vacuum Pressure Leak Test.

From www.youtube.com

VLT ECO Vacuum Leak Tester (Eco Model) Tetra Pak test / Test d Vacuum Pressure Leak Test Enclose sample in sealed an tight chamber. To ensure and maintain the pressure/vacuum; This is certainly the case with leak detection, with four main methods being employed: Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. The essential guide to vacuum leak detection. Ensure you have the necessary. Vacuum decay leak testing is commonly used. Vacuum Pressure Leak Test.

From www.aliexpress.com

Universal Radiator Pressure Tester and Vacuum Type Cooling System Kit Vacuum Pressure Leak Test Ensure you have the necessary. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Tightness (or “the absence of leaks”) is required for numerous reasons, including: Vacuum decay testing. Vacuum Pressure Leak Test.

From www.aliexpress.com

Buy Fuel Pump & Vacuum Tester Gauge Leak Carburetor Vacuum Pressure Leak Test To ensure and maintain the pressure/vacuum; Ensure you have the necessary. Enclose sample in sealed an tight chamber. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. A vacuum decay. Vacuum Pressure Leak Test.

From sanatron.com

Force Decay Leak Testing Vacuum Pressure Leak Test Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. Tightness (or “the absence of leaks”) is required for numerous reasons, including: This is certainly the case with leak detection, with four main methods being employed: Enclose sample in sealed an tight chamber. Ensure you have the necessary. In addition, we distinguish, based on the direction. Vacuum Pressure Leak Test.

From www.startimesupply.com

Diablo Vacuum Leak Tester, DIABLOVT Star Time Supply Vacuum Pressure Leak Test In addition, we distinguish, based on the direction of flow for the fluid, between the. Enclose sample in sealed an tight chamber. Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. Tightness (or “the absence of leaks”) is required for numerous reasons, including: A vacuum decay leak test evacuates air from the part or assembly. Vacuum Pressure Leak Test.

From www.youtube.com

How to perform a pressure leak test using the Fluke 729 YouTube Vacuum Pressure Leak Test The essential guide to vacuum leak detection. This is certainly the case with leak detection, with four main methods being employed: Tightness (or “the absence of leaks”) is required for numerous reasons, including: A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Vacuum decay testing is as sensitive as pressure decay testing and has. Vacuum Pressure Leak Test.

From www.desertcart.lk

Buy Brenkumoty coolant tester 14 Pieces Of Water Tank Pressure Leak Vacuum Pressure Leak Test A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. The essential guide to vacuum leak detection. Ensure you have the necessary. In addition, we distinguish, based on the direction. Vacuum Pressure Leak Test.

From www.desertcart.com.om

Buy Radiator Pressure Tester, 28 Pieces Cooling System Pressure Tester Vacuum Pressure Leak Test A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. Ensure you have the necessary. In addition, we distinguish, based on the direction of flow for the fluid, between the. To ensure and maintain the pressure/vacuum; Enclose sample in sealed an. Vacuum Pressure Leak Test.

From techotrix.com.au

Leak Test Pressure/Vacuum Techotrix Vacuum Pressure Leak Test In addition, we distinguish, based on the direction of flow for the fluid, between the. The essential guide to vacuum leak detection. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. A vacuum decay leak test evacuates air from the part or assembly to. Vacuum Pressure Leak Test.

From homeadvisorblog.com

How to Check for Vacuum Leaks Without a Smoke Machine Home Advisor Blog Vacuum Pressure Leak Test Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. In addition, we distinguish, based on the direction of flow for the fluid, between the. This is certainly the case with. Vacuum Pressure Leak Test.

From www.multitechnic.no

IP Tester Vacuum and Pressure leaks Multitechnic AS Vacuum Pressure Leak Test A vacuum decay leak test evacuates air from the part or assembly to detect leaks. In addition, we distinguish, based on the direction of flow for the fluid, between the. To ensure and maintain the pressure/vacuum; This is certainly the case with leak detection, with four main methods being employed: Vacuum decay testing is as sensitive as pressure decay testing. Vacuum Pressure Leak Test.

From www.made-in-china.com

Leak Tester ASTM D3078 Negative Pressure Vacuum Leaking Test Equipment Vacuum Pressure Leak Test A vacuum decay leak test evacuates air from the part or assembly to detect leaks. Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. The essential guide to vacuum leak detection. This is certainly the case with leak detection, with four main methods being employed: To ensure and maintain the pressure/vacuum; Enclose sample in sealed. Vacuum Pressure Leak Test.

From minder-hightech.en.made-in-china.com

Vacuum Pressure Sealing Tester / Air Leak Test Detector China Vacuum Pressure Leak Test Vacuum decay testing is as sensitive as pressure decay testing and has similar precision. The essential guide to vacuum leak detection. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. A vacuum decay leak test evacuates air from the part or assembly to detect. Vacuum Pressure Leak Test.

From www.industrialpress.com.my

LABTHINK MFY01 Leak Tester, Vacuum leak testing equipment Industrial Vacuum Pressure Leak Test This is certainly the case with leak detection, with four main methods being employed: Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical housings. Enclose sample in sealed an tight chamber. The essential guide to vacuum leak detection. To ensure and maintain the pressure/vacuum; Vacuum. Vacuum Pressure Leak Test.